MB 820

Marine og industrimotor, V12 med ca 60 liter slagvolum.

Benyttet som fremdriftsmotor i hurtigbåter, ubåter (Kobben-klassen).

MB 820

Ble med inn i mtus sortiment som mtu serie 493

-- MTZ Nr. 4 Juli/August 1950 DK 621.431.72

Fra Overingeniør Otto Schilling, Stuttgart-Untertürkheim --- (Denne artikkelen er oversatt til Norsk, og er fra 1950)

Den nye 800 HK Daimler-Benz lokomotivmotoren enten med mekanisk overlader (kompressor), eller eksosturbin (turbo)

N r. 4 Juli/August 1950 DK 621.431.72 The new 800-hp Daimler-Benz railcar diesel engine with mechanical powered charger or exhaust charging.

Daimler-Benz Aktiengesellschaft, as the oldest factory for high-speed internal combustion engines, has always kept up with the development of railcars by creating suitable drive motors. However, while the preference was given to low-speed engines elsewhere, the aim here was to quickly build running machines for this purpose.

It was recognized early on that the fast-running engine has extraordinary advantages in terms of its weight and its installation dimensions, and that only with it is it possible to accommodate greater performance in the available space in the vehicle.

Of course, special efforts were needed to achieve the reliability and long life, which are particularly important for railcars, in spite of the fastness. These very aspects have always been decisive in the design and choice of building materials for this type of engine. These principles have succeeded not only in achieving the usual lifespan of slower engines, but also in significantly increasing them.

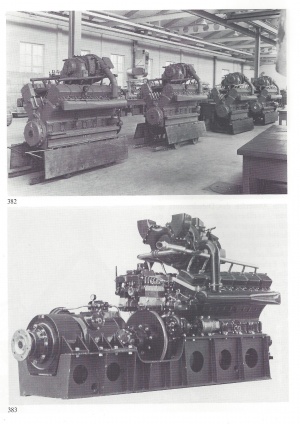

Recently, the Daimler-Benz AG has a 800-horsepower diesel motor to be reported here. It is the logical further development of the 450-hp MB 806 diesel engine built before the war and tested in many kilometres. (Picture 1.)

As with him in particular the experience was collected, which are the rough railway operation, he should be briefly mentioned here again, although he has been briefly described in the context of a larger essay (Bushman, railcar engines, MTZ 1940, Issue 5)

The MB 806 was built as a 12-cylinder V engine, initially without charging and made on the brake about 650 hp at n = 1400 rpm. Since the vehicles in which it was installed required only 450 hp, this resulted in a considerable power reserve, which was very expedient for railcars with regard to achieving the longest possible service life of the engine.

With these engines running times of 150 000 km and more until the first major overhaul he enough, which in terms of the type of vehicles concerned (it was express railcar) an operating time of about 3000 hours equals. The installation of the engine in a bogie of the company Westwaggon in Cologne, coupled with a generator of the company BBC Mannheim, shows Figure 2. Shortly before the war, this engine is already with Aufla - tion, by a turbocharger vertical design (Type Büchi), built. With charging, the power was about 750 hp at n = 1400 rpm. The thermal load corresponded approximately to that of 450 hp at the uncharged engine.

The installation in a vehicle was in this engine, which is also described in the above-mentioned essay, unfortunately no longer possible because of the outbreak of war. A promising development would have to be stopped by a war.

After the war, the development of this engine was immediately resumed, despite the difficulties caused by the almost complete destruction of the factory. All facilities, models etc. were lost. Therefore, a completely new model had to be developed in which, however, one could evaluate the rich operational experience which had resulted in the pre-war railcar engines for the new machines.

Likewise, the manifold fabrication and design experiences were taken into account, which could be acquired in all areas of large engine construction true to the end of the war. Many insights, in particular the choice of suitable materials, surface refinement, etc., could be taken during the development of the persons and truck engines simultaneously being manufactured in other departments of the plant. The Federal Railways, for which the new railcar engines are primarily intended and with which mainly due to the installation collar also always close contact was required for the new railcars a much higher performance. Therefore, the total stroke volume was increased from 50 to 57.2 liters and the maximum power set to N = 800 hp with charging at n = 1400 rpm.

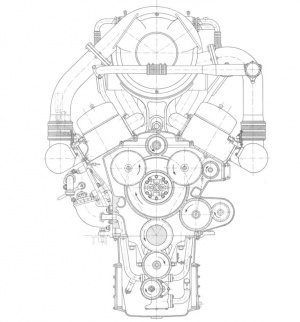

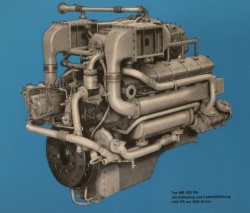

The new diesel engine MB 820 also has 12 cylinders in V-arrangement. He has 172 mm bore at 205 mm stroke. For the purposes of the Federal Railroad, he will also be equipped again with an exhaust charging group. It can also be delivered with mechanically driven loader. This design also shows great advantages and has proven very well in the built during the war large marine engines and aircraft engines.

In particular, for an operation with rapidly changing load, the mechanically driven supercharger is very suitable, because it follows sudden changes in load inevitably immediately and always provides a sufficient amount of air for combustion available. In the case of the exhaust gas charger, a rapid transition to a higher load requires a greater amount of exhaust gas to be produced in order to accelerate the supercharger wheel coupled to the exhaust turbine to the required supercharger speed. In this period, which may take 15-25 seconds, the diesel engine operates under air deficiency.

However, the mechanical supercharger, whose speed is chosen so that the required amount of air corresponds to the maximum power, requires too much air when moving to low load, but this is less unfavourable to the engine than working under air deficiency. Although the power required to drive the mechanical supercharger must be additionally applied by the working piston, on the other hand, there is a backflow of the exhaust gases to the piston in the exhaust gas turbine, which also costs power and additionally warms the cylinder charge with fresh air and therefore reduces it. Detailed comparative tests have shown that when the mechanical supercharger is designed for an air throughput which gives approximately the same excess air ratio for the amount of air participating in the combustion as for the exhaust gas charger, the fuel consumption differs only insignificantly. The difference after tests was about 5% at full load and n = 1400 rpm and 3% at part load and n = 1000 rpm. At lower speeds, the difference is even lower. On average, which probably corresponds to the practical operation most, ie about 4% (Figure 7).

Therefore, if the mechanically driven supercharger also has an insignificantly higher fuel consumption, then there are other benefits: The exhaust back pressure is lower, as well as the exhaust temperature almost over the entire work area, since the slightly higher compression pressures cause excellent flushing. Only at higher speeds outweighs the exhaust temperature of mechanical supercharger et what due to the influence of increasing load capacity.

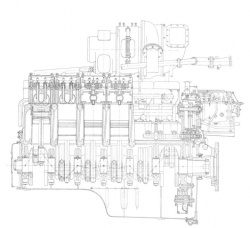

Other advantages are the low weight of the mechanically driven supercharger, which weighs only about 50 kg, compared to the current weight of the exhaust gas charger of about 300 kg; then the smaller space requirement and the complete freedom of the loader of heat loads by exhaust gases. In contrast, the exhaust gas charger has the advantage that it acts silencing and a special muffler can be omitted in most cases. Both the mechanically driven supercharger and the exhaust pipe have been tested on the engine in several endurance races. Both will be well preserved if used where appropriate for their particularity. Fig. 3 shows the engine with mechanically driven loader and Fig. 4 with the system Büchi from the company BBC Mannheim.

The diesel engine is exactly the same in both cases. The mechanically driven loader receives its drive through spur gears from the crankshaft. An intermediate slip clutch protects the fast-running loader wheel against excessive acceleration and deceleration. BBC Mannheim's System Büchi exhaust charge unit is the latest development of this company. In order to keep the bearings of the high-speed turbine shaft easily accessible, the horizontal design was chosen. The bearings and exhaust parts of the turbine are water cooled. The turbine is positioned exactly above the center of the engine to provide the shortest possible equal and equal exhaust gas supply to the turbine and thereby maximize the utilization of the dynamic energy of the exhaust gases. By a large overlap of the outlet end and the beginning of intake on the control shaft, a good flushing of the combustion chamber and cooling of the piston crown and the outlet valves is achieved. Likewise, there is a significant reduction in the temperature of the exhaust gases behind the exhaust valves. So is z. Eg the exhaust temperature at Pme = 9 kg / cm2 with charging not higher than at Pme = 6 kg / cm2 without charging. The mechanical stress of the engine is only slightly increased by the charge. The structure of the motor in section is shown in Figure 5. The up to the cylinder head raised crankcase is made of light metal. The crankshaft runs in lead-bronze bearings. It is so strong that it is vibration-free over the whole speed range. Case steel was chosen as the material because it gives the largest surface hardness, namely 60 to 64 Rockwell, and therefore guarantees the lowest wear. The crankshaft is balanced by six counterweights. The connecting rod bearings of the two rows of cylinders are offset from one another, whereby twelve identical piston rods of simple and lightweight design are possible. The material for the wet cylinder liners has been carefully selected in order to obtain even the least amount of wear. They are made of alloyed gray cast iron with a Brinell hardness of 240-250.

The Daimler-Benz pre-chamber has been retained for the combustion process because it has been found to be most suitable for engines requiring minimum wear, smoke, low gear and long life. It has been refined, however, so that the fuel consumption can be obtained with the most appropriate setting of the injection, as can be seen in Figure 6. It concerns the full load and partial load consumption of the exhaust gas charger. At Pme = 9 kg / cm2 and n = 1400 rpm, consumption is about 170 g / PSh and the minimum consumption at Pme = 7.2 kg / cm2 and n = 800 rpm is about 157 g / PSh. Figure 7 shows the performances over the speed, as they are usual for hydraulic or electrical transmission. They show a propeller-like characteristic. In connection with the performances, the fuel consumption and the exhaust temperature behind the cylinders, the supercharger compression pressures and the exhaust back pressures are shown, as with the exhaust gas charger and mech. driven loader have been measured. The prechamber with the burner and the injector are centrally located in the single cylinder heads. The pistons are forged from light metal. The curved shape of the piston crown results in a good turbulence of the fire gases flowing out of the antechamber with the combustion air in the main chamber. Also in the railcar engines attempts are underway to chrome the top piston ring, which has been very well preserved in motor vehicle engines. It is thus intended to further reduce the in itself minimal wear of the cylinder liners. The two fuel pumps are arranged with the controller on the rear end of the engine and are easily accessible here. The regulator is oil pressure actuated and automatically stops the speed which is set via the chain and sprockets by an electric speed control located on the vehicle frame next to the engine. The speed controller is electrically operated from the cab. An injection torque adjuster automatically ensures the exact speed-dependent start of injection of the fuel into the cylinder. This is very important because errors in the setting of the injection torque can result in overheating in the combustion chamber with cracks in the cylinder head and piston crown. It is a small governor at the end of the control shaft, which rotates the fuel pumps with respect to the crankshaft by means of oil pressure piston.

For starting, it is planned to install a 15hp 24V or 25hp 110V Bosch starter that engages a ring gear on the flywheel. It is also possible to install a Bosch alternator GUL 1400/24/1000 with 1400 watts. - The necessary accessories for operating the engine have been carefully developed. The lubricating oil circuit (Fig. 8) has been split into two parts to relieve the main oil pump from the resistances of the lubricating oil cooler, mainly with a cold machine. In the main circuit, the lubricating oil is sucked out of the tub and printed in the various bearings via a lubricating oil filter consisting of pre-filter and fine filter. In the second cycle, the oil is also sucked out of the tub and back through the lubricating oil recooler, which is designed as a heat exchanger. conveyed into the oil pan. Special attention was paid to the filtering of the lubricating oil. In co-operation with the company Mann & Hummel a combined filter was developed, which consists of a prefilter with three Spaltfiltereinsätzen and a fine filter with two Siebfiltereinsätze in direct connection and which was allowed to meet all requirements.

An electric pre-pumping unit creates the necessary oil pressure before starting. A fuse is made that without enough oil pressure the engine cannot be started at all. This is a measure that will greatly contribute to extending the life of the engine.

Since the temperature of the lubricating oil also has an influence on the durability of the bearings, it is recooled in the heat exchanger by a special cooling water circuit. For this purpose, the cooling water pump has two centrifugal wheels. One is concerned with the hydraulic circuit for the cooling chambers of the engine and the other one prints a second part of the cooling water, which is cooled deeper, over the lubricating oil heat exchanger. In this way, the temperature of the lubricating oil can be maintained at 75 ° C, although the water temperature in the cold rooms is 85 ° C.

Four large air purifiers with a total area of 0.5 m2 for cleaning the combustion air, which has been taken from a place which is as cool and dust-free as possible, complete the accessories of the engine. In particular, great efforts have been made by the railway central office of the Federal Railway to develop filter patterns through cooperation between the relevant companies, which, in addition to a 97% degree of purification, require cleaning only after one-week operation. (4221)