OM 601

Tilbake til oversikt over Mercedesmotorer

OM 601 var etterfølgeren til OM 616. Den er en del av familien som består av OM 601, OM 602, og OM 603.

Introdusert i 1983, for å erstatte de aldrende OM 616 og OM 617.

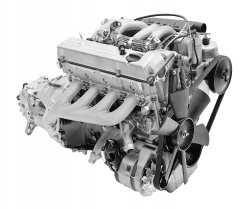

Mercedes OM 601 er den minste av disse, 4 sylindre, med overliggende kam, og aluminiumstopp, i motsettning til forgjengerens støpejernstopp. Den første versjon hadde en ytelse på 72 HK. Sammelignet med OM 616, som var på 2,4 Liter og produserte 67 HK. Dreiemomenter var dog lavere en i OM 616, som i sin siste versjon hadde 132 Nm.

Mercedes-Benz OM 601

The 2.0 liter non-USA unit was on sale for nearly a year longer than the 2.2 liter USA emissions compliant version. This very slight increase in displacement, likely the reason for the delayed release, reduced emissions out of the tail pipe in order to meet the US Federal EPA requirements, and (according to the factory) with no horsepower or performance difference. California versions were sold with an EGR (exhaust gas recirculation device to control NOx emissions). Although not known for causing as many problems (nor as serious of problems) as the 'trap oxidizer,' the EGR still has a history of causing drive-ability and overall operational performance issues when it is not functioning to spec. The trap oxidizer was another common emission control device first seen on California Mercedes-Benz Diesel cars and, later, on Federal Emissions Diesels.

In very few respects the OM-601 Diesel engine is similar to the legendary reliable and long lasting 'million mile' OM-61X series Diesels of the 1970s and '80s. The similarity ends there. The 60x series ushered in the use of an aluminum head on and iron block for Mercedes, unlike the venerable 61x series born in the early sixties. The prechamber design was a revolutionary break through for it's time and remained in use from 1983 to 1999 when replaced by the current CDI rail injected design. OM-601s can be just as reliable as the old OM-61X family for hundreds of thousands of miles if properly maintained (OM-602s and OM-603s have their own inherent issues due to their design variations on the OM-601). As with most Diesels, when compared with a gasoline engine in the same operating conditions: i.e. short trips in the city with lots of cold starts, a Diesel needs less maintenance. The majority of the maintenance procedures are very simple for the average do-it-yourselfer to perform.

Maintenance for the EARLY OM-60X including the later OM-606 family is somewhat similar to the OM-61X family. They all will obviously need oil and filter changes. (Oil changes in Mercedes 60X/61X passenger car Diesel engines are the easiest of just about any vehicle ever... especially the filter due to its accessibility from the top of the engine bay. The only extra step is removing and reinstalling the engine sound encloser w/ 4 8mm screws, and that's only necessary if the oil is not sucked out through the dipstick.) Both fuel filters need replacing annually or 12K miles. Both families require, in around 150000 mi| intervals, the fuel injector return lines be replaced once Diesel fuel starts to leak out of them and puddle up around the injectors (this procedure requires only a knife, maybe some pliers to pull the old lines off, and no more than 60 cm of special hose easily obtained from the MB Dealership (at least one spool in stock usually) and fortunately costing only dollars per foot). It is recommended that a bit extra hose be purchased as spare for unforeseen circumstances. This circuit is what daisy chains the fuel injectors together, allowing excess fuel supplied by the fuel and injection pumps to the injectors to return back to the fuel tank. Not required but recommended for ALL DIESEL ENGINES, at least once a year, is using a fuel system cleaner such as "Diesel Purge" by Lubro Moly. (The best results are accomplished with a simple procedure usually requiring only a screw driver [supplied in the car's factory tool kit], a glass or other 'fuel safe' jar, possibly a length of the replacement rubber hose used for the fuel return line [different from the injector daisy chain hose], a slight incline to keep gravity from pulling fuel out of the disconnected hard lines to/from the tank [this is usually learned the hard way after roughly a gallon of Diesel fuel is lost on the ground], and last but in no way least: allowing roughly 20 minutes per 16 oz of Diesel purge used to run the engine). Yes, the engine is run on the Diesel purge out of a jar!) Glow plugs burn out with years of use and need replacement more often than spark plugs in a gasoline engine with similar operating conditions (especially with lots of cold starts). Glow plugs are admittedly typically harder to replace than spark plugs in a common arrangement. Despite the common maintenance procedures between the OM-61X family and the OM-60X family, there is one key procedure the OM-60X eliminated: VALVE ADJUSTMENTS!

One main design differences between the OM-60x and OM-617 include use of an aluminum head as opposed to cast iron, this helps make the OM-60x weigh Skriptfeil: Ingen modul med navn «convert». less than the OM-61x it replaced. Also the cylinders are on a 15 degree slant to the right instead of vertically arranged as in the OM-61X engines. This gives more room under the hood directly above the engine for the longer intake runners which help boost the OM-601's torque. The OM-616 had solid valve lifters that required adjustment roughly every Skriptfeil: Ingen modul med navn «convert».. This procedure requires special tools (bent wrenches) that are moderately expensive to buy and not trivial to fabricate for the D-I-Y owner. The OM-60X family introduced hydraulic lifters for Mercedes-Benz Diesel engines. This is the sole reason for requiring no valve adjustments for the life of the engine. The new OM-601 also introduced a multi-ribbed serpentine v-belt to the Mercedes-Benz Diesel family, eliminating the "arguably 'more reliable'" multi-belt accessory setup. The following seems to be the ONLY argument against a serpentine belt: if one belt breaks, say for the A/C compressor, the car is OK for a while because it still has the alternator to charge the battery, the water pump to cool the engine, and the power steering pump to have full control of the vehicle. If the VERY unlikely situation of a broken serpentine arises (really only possible with a defective, or extremely OLD, or improperly installed belt), the car MUST BE STOPPED IMMEDIATELY TO PREVENT OVERHEATING!!! The car will still run, but not for long, and it will be hard to steer without power assist. Arguments against the multi-belt are the possibility for needing different sized belts, that replacing ONE broken or damaged belt can be tedious due to having to take them all off to get to the rear belt, and most importantly the belts are inherently smaller and not as strong as the single serpentine setup, thus being more prone to breaking. V-belts are also less efficient, and wear faster than a serpentine belt.

Common complaints are blown head gaskets and warped cylinder heads due to overheating, blamed on the use of aluminum for the head and not cast iron. Most engines can tolerate a level of overheating, but all will fail eventually if overheated long and hot enough. An OM601 is not really any more prone to overheating than the OM616, but it is much less tolerant of it. Properly maintained examples of the OM-601 are known to go Skriptfeil: Ingen modul med navn «convert». and more without needing a rebuild. With high miles, a well maintained OM-601 should only ever need a head gasket and timing chain, hopefully before failure of either, but only up around Skriptfeil: Ingen modul med navn «convert»..

In the Daimler-Benz W201 chassis 190D 2.0L (Euro) and 2.2L (USA), the OM-601 returned good fuel economy numbers for its time: around 30+ MPG city and 45+ highway with the automatic. According to the EPA numbers seen with the 5-speed, the 190D 2.2L returned 36 MPG and 55 MPG city and highway, respectively. Both versions were putting up very impressive fuel economy numbers, even by 'MODERN' standards!! Speaking from experience, an OM-601 automatic W201 chassis from 1984 will (in good running condition) return NO LESS than 30MPG in the city driving far more briskly than the traffic around!!!

Not only was the OM-601 more fuel efficient than the OM-616, it was dramatically quieter. This is in part due to sound encapsulating under chassis pans below the engine and transmission. These covers also prove to be most valuable as the car ages, catching the all too common oil drippings, which can be particularly objectionable on a diesel due to the oil's soot load. Other soundproofing on the later OM-60X cars included special engine compartment walls similar in construction to the under chassis pans: fiberglass with a foam lining. The hood too is lined with foam, thus giving a whole new QUIET Diesel car driving experience by the time period's standards.

The camshafts and fuel injection pump are driven by a duplex chain from the crankshaft. A separate single row chain drives the oil pump from the crankshaft.

Fuel injection is indirect via a prechamber arrangement. Upon visual comparison, the Bosch PES-4M in-line injection pump used is somewhat similar to the mechanical fuel injection pump that the WWII Messerschmitt Bf109 fighter plane which ironically was powered by a Daimler-Benz DB 601 thru DB 605 gasoline supercharged inverted V-12 displacing 33.9 Liters (2069 cu. in.). The OM-60X's injection pump too is a mechanical fuel injection unit with a 5,150 RPM (+ or - 50 RPM) mechanical governor, automatic altitude compensation, and a 'load sensing' automatic idle speed control. The pump is lubricated by a connection to the engine oil circulation and the fuel lift pump is mounted on the side of the injection pump. Not uncommon to leak, this connection's seal is not overly difficult to replace for the determined (it is pretty time consuming and correct reassembly is an obvious must), capable (correct tools, skills, etc.), and well informed (specifically to the exact or very similar procedure) do-it-yourself owner.

Similar to the OM-61X family, a vacuum-operated stop control was employed. Should the vacuum stop control fail to cut the fuel at shut down (usually caused by a vacuum leak), the engine could be stopped by hand under the hood of the car. The stop lever on the injection pump (accessed through the intake runners on the OM-601) can be depressed by hand to manually stop the engine, even with the key in the 'run' position. It is recommended to practice this procedure until it is not difficult to find the lever, as it is not out in the open as it was on the OM61X engines.

Preheating at cold start-up is accomplished by glow plugs with an automatic control of preheating time. Early models simply ended the glow cycle once the engine was running, or after around 45 seconds if the engine is not running. Later models (around 1987) of the OM-601 2.0 liter, incorporated the same system as the OM-602 and OM-603 as seen in the US. The main difference was this system would run the glow plugs for a short time after the engine was running on cold startups. This was to reduce emissions and help below operating temperature performance, but also dramatically shortened glow plug life.

All Mercedes-Benz Diesel engines were, and should still be if they aren't now, produced with block heater elements already installed. Only a block heater power cord was needed to use them...Which was ONLY an option available through the MB Dealership, and was always installed by the MB Dealership's pre-delivery preparation technician, that is if the block heater was ordered at the time of purchase of the vehicle. The Installation was logged in the owner's maintenance booklet, and also stored in the MB Dealerships' own service record history (logging the installation) was a tear out sheet from the owner's maintenance booklet. Installation was simple, making an often used or old cord easily replaceable. Moreover, the MB Dealership parts department price for a new block heater power cord is very reasonable, around $20 US in 2005... And they are easily obtained if, on the rare occasion, none are in stock.

Use of the block heater was recommended in climates where it drops below 10 °F for long periods. In less frigid environments the block heater proved to be an invaluable LUXURY feature. It allowed the car to register heat on the engine temperature gauge during the pre-glow time of the glow plugs. Even on a 20 °F morning the engine would be at a nice 30-40C, not really requiring the use of the glow plugs, but they definitely aid in creating a smoother start up and initial few moments of idling... Most noteworthy though, was how the car would have heat right at start up! So much for wanting heated seats!!

In the November 1984 issue of Car and Driver Magazine Brock Yates describes the OM 601 powered 190D versus the Gasoline M-102 powered 190E 2.3 around a track as, “…The Diesel is a Diesel. Nothing more nothing less. It is superbly quiet and well mannered as the breed goes…” Proving that in its time it was turning the tides for Diesel powered vehicles. The OM-601 can be described as an early segue to the modern CDi and BlueTech engines that Mercedes-Benz produces today.