OM 906: Forskjell mellom revisjoner

mIngen redigeringsforklaring |

mIngen redigeringsforklaring |

||

| Linje 369: | Linje 369: | ||

| | | | ||

|} | |} | ||

---- | |||

=== The new six-cylinder diesel engine OM 906 LA from Daimler-Benz === | |||

(From a article in MTZ | |||

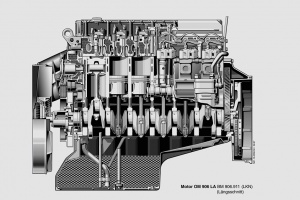

With the introduction of the new OM 906 LA six-cylinder in-line engine, Daimler-Benz completes the 900 engine series (BR 900), whose four-cylinder variant, the OM 904 LA, has been on the market since 1996. These engines are designed for both light-duty and heavy-duty commercial vehicles. With a displacement of 6.4 liters, a maximum rated output of 205 kW at 2,300 rpm, and maximum torque of 1,100 Nm at 1,300 rpm, the new engine enters a power range previously covered by engines with significantly larger displacement. This article introduces the new six-cylinder engine. | |||

====== Introduction ====== | |||

The introduction of the new six-cylinder OM 906 LA diesel engine completes the renewal of the engine product range for commercial vehicles, following the introduction of the four-cylinder OM 904 LA and the 500 series (BR 500) engines in 1996. The design of the OM 906 LA took into account the diverse applications of both Daimler-Benz's global vehicle concepts and those of other automobile manufacturers, each with its own unique requirements. With its current power range of 170 to 205 kW, particularly for on-road use, the OM 906 LA enters a performance segment previously covered by significantly larger displacement engines, such as the 11-liter OM 441 LA. This was addressed through the use of modern technologies and systems, as well as specific testing to ensure a B10 service life of 600,000 km in heavy-duty long-haul applications. This article discusses the design, testing, and, in particular, the comparison with the larger engines previously used in this power segment. | |||

====== Product concept ====== | |||

The new OM 906 LA six-cylinder engine builds on the basic concept and features of the OM 904 LA four-cylinder engine, introduced in 1996. Both engines were planned as a single engine series from the outset. The design considerations for a new engine series in the power segment between the 600 Series, which was further developed from passenger car diesel engines for commercial vehicle use, and the new V-engines of the 500 Series introduced with the Actros, were essentially based on the following basic requirements: | |||

– Low life cycle costs | |||

– Compliance with global emissions standards | |||

– Heavy-duty characteristics in terms of service life, fuel consumption, and maintenance intervals | |||

– Suitable for application in all vehicles used worldwide by Daimler-Benz and other automobile and equipment manufacturers | |||

– Suitable for use as a horizontal engine in city buses | |||

– High engine braking performance | |||

– Low noise emissions. | |||

Another key criterion in the design of the new engine series was that four-cylinder engines had to be used in the power segment up to 150 kW, especially for distribution transport, due to their short overall length and the associated design advantages for the vehicle (low entry, level cab floor, and thus free access). | |||

With a stroke/bore ratio of 1.27, a mean effective pressure of approximately 17 bar at rated speed, and approximately 22 bar at maximum torque, the technical data shown in Figure 2 resulted. The six-cylinder OM 906 LA engine, in particular, with its maximum output of 205 kW, covers a power segment previously achieved by the large 400 series engines with displacements of 11 l and 12 l. Therefore, a guaranteed B10 service life of 600,000 km was a key focus of testing for the OM 906 LA. The choice of injection system had a significant influence on the engine design. The plug-in pump concept still represents the best solution today, even compared to the common rail systems currently under development, for displacements >1 l per cylinder and the exhaust gas test cycles applicable to commercial vehicles, and it still has sufficient potential for further development in the foreseeable future. The key features of the BR 900 engines have already been described in detail in previous publications [1, 2, 3, 4, 5, 6]. The following section discusses the further development measures following the series launch of the OM 904 LA four-cylinder engine. | |||

====== Injection system with leak-free single-spring nozzle holder ====== | |||

The OM 904 LA was introduced with the dual-spring nozzle holder concept, particularly due to its noise advantages during idle operation. Since then, the injection system has been further developed so that the required idle noise levels can also be achieved with a single-spring nozzle holder combination without leak-through fuel return ("leak-free"). By eliminating the leak-through fuel return, it has become possible to reduce the nozzle opening pressure – and thus the idle noise – of the single-spring nozzle holder to the low level of the first stage of the dual-spring nozzle holder. | |||

The hydraulic pressure built up during the injection process in the closed spring chamber of the leak-free nozzle holder increases the closing force on the nozzle needle, thus ensuring blowback-free operation of the injection system despite the low opening pressure – set via the compression spring. | |||

To reduce the number of variants, a uniform injection nozzle is used for all engine variants of the 900 series. The resulting uniform injection hole cross-section results in maximum injection pressures of 1,800 bar in the most powerful variant of the OM 906 LA. The same nozzle holder was used for this application as in the 500 series, adapted to the increased stress by selecting a higher-quality material and careful machining to avoid notch effects. | |||

- | |||

''Mercedes Benz OM906 - Daimler-Benz OM906'' | ''Mercedes Benz OM906 - Daimler-Benz OM906'' | ||

[[Kategori:Daimler-Benz dieselmotor]] | [[Kategori:Daimler-Benz dieselmotor]] | ||

Revisjonen fra 1. mai 2025 kl. 13:49

Tilbake til oversikt over Mercedesmotorer

OM 906

| OM 906 | kW | HK | RPM | |

|---|---|---|---|---|

| .900 | 205 | 279 | ||

| .901 | 170 | 231 | ||

| .903 | 205 | 279 | ||

| .910 | ||||

| .911 | ||||

| .912 | ||||

| .913 | ||||

| .914 | ||||

| .915 | ||||

| .916 | ||||

| .917 | 170 | 231 | ||

| .918 | 180 | 245 | ||

| .919 | 180 | 245 | ||

| .920 | 170 | 231 | ||

The new six-cylinder diesel engine OM 906 LA from Daimler-Benz

(From a article in MTZ

With the introduction of the new OM 906 LA six-cylinder in-line engine, Daimler-Benz completes the 900 engine series (BR 900), whose four-cylinder variant, the OM 904 LA, has been on the market since 1996. These engines are designed for both light-duty and heavy-duty commercial vehicles. With a displacement of 6.4 liters, a maximum rated output of 205 kW at 2,300 rpm, and maximum torque of 1,100 Nm at 1,300 rpm, the new engine enters a power range previously covered by engines with significantly larger displacement. This article introduces the new six-cylinder engine.

Introduction

The introduction of the new six-cylinder OM 906 LA diesel engine completes the renewal of the engine product range for commercial vehicles, following the introduction of the four-cylinder OM 904 LA and the 500 series (BR 500) engines in 1996. The design of the OM 906 LA took into account the diverse applications of both Daimler-Benz's global vehicle concepts and those of other automobile manufacturers, each with its own unique requirements. With its current power range of 170 to 205 kW, particularly for on-road use, the OM 906 LA enters a performance segment previously covered by significantly larger displacement engines, such as the 11-liter OM 441 LA. This was addressed through the use of modern technologies and systems, as well as specific testing to ensure a B10 service life of 600,000 km in heavy-duty long-haul applications. This article discusses the design, testing, and, in particular, the comparison with the larger engines previously used in this power segment.

Product concept

The new OM 906 LA six-cylinder engine builds on the basic concept and features of the OM 904 LA four-cylinder engine, introduced in 1996. Both engines were planned as a single engine series from the outset. The design considerations for a new engine series in the power segment between the 600 Series, which was further developed from passenger car diesel engines for commercial vehicle use, and the new V-engines of the 500 Series introduced with the Actros, were essentially based on the following basic requirements:

– Low life cycle costs

– Compliance with global emissions standards

– Heavy-duty characteristics in terms of service life, fuel consumption, and maintenance intervals

– Suitable for application in all vehicles used worldwide by Daimler-Benz and other automobile and equipment manufacturers

– Suitable for use as a horizontal engine in city buses

– High engine braking performance

– Low noise emissions.

Another key criterion in the design of the new engine series was that four-cylinder engines had to be used in the power segment up to 150 kW, especially for distribution transport, due to their short overall length and the associated design advantages for the vehicle (low entry, level cab floor, and thus free access).

With a stroke/bore ratio of 1.27, a mean effective pressure of approximately 17 bar at rated speed, and approximately 22 bar at maximum torque, the technical data shown in Figure 2 resulted. The six-cylinder OM 906 LA engine, in particular, with its maximum output of 205 kW, covers a power segment previously achieved by the large 400 series engines with displacements of 11 l and 12 l. Therefore, a guaranteed B10 service life of 600,000 km was a key focus of testing for the OM 906 LA. The choice of injection system had a significant influence on the engine design. The plug-in pump concept still represents the best solution today, even compared to the common rail systems currently under development, for displacements >1 l per cylinder and the exhaust gas test cycles applicable to commercial vehicles, and it still has sufficient potential for further development in the foreseeable future. The key features of the BR 900 engines have already been described in detail in previous publications [1, 2, 3, 4, 5, 6]. The following section discusses the further development measures following the series launch of the OM 904 LA four-cylinder engine.

Injection system with leak-free single-spring nozzle holder

The OM 904 LA was introduced with the dual-spring nozzle holder concept, particularly due to its noise advantages during idle operation. Since then, the injection system has been further developed so that the required idle noise levels can also be achieved with a single-spring nozzle holder combination without leak-through fuel return ("leak-free"). By eliminating the leak-through fuel return, it has become possible to reduce the nozzle opening pressure – and thus the idle noise – of the single-spring nozzle holder to the low level of the first stage of the dual-spring nozzle holder.

The hydraulic pressure built up during the injection process in the closed spring chamber of the leak-free nozzle holder increases the closing force on the nozzle needle, thus ensuring blowback-free operation of the injection system despite the low opening pressure – set via the compression spring.

To reduce the number of variants, a uniform injection nozzle is used for all engine variants of the 900 series. The resulting uniform injection hole cross-section results in maximum injection pressures of 1,800 bar in the most powerful variant of the OM 906 LA. The same nozzle holder was used for this application as in the 500 series, adapted to the increased stress by selecting a higher-quality material and careful machining to avoid notch effects.

-

Mercedes Benz OM906 - Daimler-Benz OM906