MB 873: Forskjell mellom revisjoner

Ingen redigeringsforklaring |

mIngen redigeringsforklaring |

||

| Linje 11: | Linje 11: | ||

MB 873 Ka 12-cylinder V engine with exhaust gas turbocharging and internal charge air cooling | MB 873 Ka 12-cylinder V engine with exhaust gas turbocharging and internal charge air cooling | ||

== From "Daimler-Benz High output engines - a study in compact design. == | |||

A paper published by SAE, written by O. Herschmann of Daimler-Benz A.G. 1967 | |||

'''ABSTRACT:''' To meet the increased power demands for special vehicles, Daimler-Benz started the development of a compact, liquid-cooled diesel engine family some 12 years ago. The objective of this development was to obtain a maximum output from a given bulk volume while maintaining well-known diesel engine characteristics. The basic layout of this family was such as to offer a high degree of versatility and to allow continued development. Based on this existing engine family, the development of a 1500 hp engine was started about three years ago. Reducing the bulk volume and, at the same time, increasing the specific output, resulted in a very compact engine, producing 28.4 hp per cu ft of bulk volume. This paper presents some of the considerations made in the design of these engines and some interesting technical data. | |||

- | |||

IN THE HISTORY of Daimler-Benz, as the oldest automomobile manufacturer in the world, the development of compact high-performance engines has a long-standing tradition. | |||

It all started with the development of an engine for vehicle application some 80 years ago. This engine had to be more compact and lighter in weight than the internal combustion engines of that time. The development of this engine thus marked the beginning of what is called the "automotive age." | |||

In the future course of time, there followed the development of various engines for which compact design and high output were of decisive significance; for example, engines for racing cars, airships, and airplanes. At the same time, diesel engines for trucks, passenger cars, and locomotive and marine applications were included in the development program. | |||

Through the progress made with these engines, all types of vehicle development were stimulated. Within the framework of this development, it proved necessary to expand knowledge on the thermodynamic and combustion processes taking place within the engine, as well as to create the necessary equipment for basic research, computation techniques, and methods of measurement. At the same time, research was directed towards the mechanical and thermal loading of engine components, engine behavior, and adaptation for specific applications. | |||

Based on this knowledge, the development of a new family of four-stroke cycle diesel engines began about 12 years ago. For these engines, high output at minimum bulk volume was of special importance in meeting the particular requirement for installation in special vehicles. Furthermore, the basic design of this engine family had to be such as to permit continued development. | |||

For any such development, one must have a clear idea of the requirements and of the possibilities that exist to accomplish the goal set. Only after careful evaluation of all aspects can a decision be made on the direction that development should take. This paper reports the manner in which Daimler-Benz has dealt with these problems. | |||

BASIC CONSIDERATIONS AS TO ENGINE CONFIGURATIONS | |||

The first decision to be made is how to lay out the engine with respect to required output. This in turn raises a number of questions. For example, is the engine underrated or overrated for the vehicle in question? In other words, will the engine be operated more or less often at high loads? Is there a weight increase to be anticipated for the vehicle, or will the requirements rise in respect to mobility? | |||

The answer to these questions and the existing development schedule determine the basic engine specifications (displacement, mean effective pressure, engine speed, and piston speed) in accordance with the state-of-the-art and the foreseeable progress in this field. | |||

From an economical point of view, the basic design of an engine should remain unchanged for as long as possible. | |||

Therefore, it seemed expedient to us to plan the layout in | |||

such a manner that would lead to an engine family. With | |||

such an engine family, changing demands from the vehicle | |||

side as well as the requirements of a new project can best | |||

be met, while also offering the logistic advantage of a great | |||

many identical parts. | |||

At this point, the next decision is to select the optimum | |||

engine configuration. We believe the V-90 deg arrangement | |||

to be an optimum solution for an engine family for | |||

the following reasons: | |||

1. It represents an ideal in that the first-order reciprocating | |||

forces can be balanced by counterweights on the crankshaft. | |||

2. It offers a good compromise with regard to the housing | |||

of auxiliary units, and offers good accessibility of the | |||

engine from the top. | |||

3. It offers a favorable ratio of height to width. | |||

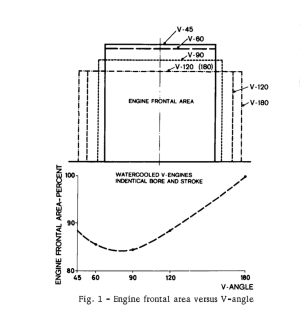

Fig. 1 shows the results of a design study for various V-angles. | |||

Going from 60 to 45 deg does not yield any further | |||

decrease of width; the step from 120 to 180 deg does not further decrease the height. As can be seen further from | |||

Fig. 1, the frontal area of the V-90 deg engine almost attains | |||

a minimum. | |||

COOLING SYSTEM - When faced with the question of | |||

whether to choose liquid-cooling or aircooling, we decided | |||

on liquid-cooling for the following reasons: | |||

1. We are of the opinion that the liquid-cooled engine | |||

allows a certain output within a given envelope to be obtained | |||

by simpler means, and feel that it involves fewer | |||

risks. | |||

2. We have found the installation space required for liquid-cooled | |||

engines, including radiator, to be less than that | |||

of an aircooled engine of identical displacement. For the | |||

latter, the cooling air ducts must also be taken into consideration. | |||

3. When installed, the liquid-cooled engine offers the | |||

advantage that the radiator may be located away from the | |||

engine. The engine can thus be mounted in places where, | |||

for various reasons, the installation of cooling air ducting | |||

would be difficult. | |||

4. The dated argument, that the liquid-cooled engine is | |||

more susceptible to trouble, more vulnerable, and more | |||

complex on account of its cooling system and the necessary | |||

piping, has become invalid, since the modem aircooled high- | |||

performance engine also needs efficient oil coolers at exposed | |||

locations and similarly requires piping. | |||

The installation of the transmission oil cooler, which is | |||

indispensable for all modern transmissions, can be accomplished | |||

more easily with liquid-cooling than with aircooling. | |||

5. Engine warmup under arctic conditions appears to be | |||

simpler with liquid-cooling. | |||

The fact that the liquid-cooled engine requires a liquid | |||

coolant is more than balanced by the above-mentioned advantages, | |||

particularly since this coolant is not required for | |||

consumption but need only be replenished. | |||

FOUR-STROKE CYCLE - In making the choice between | |||

the two or four-stroke cycle, we decided to employ the latter, | |||

not only because we have a great deal of experience | |||

with it but also because investigations conducted on two - | |||

stroke cycle engines did not encourage us to proceed with | |||

this development. | |||

[[Fil:1967 DB HSDE FIG1.png|alt=Figur 1|miniatyr|Figur 1]] | |||

{| class="wikitable" | |||

|+Tabell 1 - Engine Specifications | |||

! colspan="2" | | |||

|- | |||

|Cylinder arrangements | |||

|V-90 | |||

|- | |||

|Type | |||

|Four stroke cycle | |||

|- | |||

|Combustion system | |||

|Prechamber | |||

|- | |||

|Stroke | |||

|175 mm | |||

|- | |||

|Bpre | |||

|165 mm | |||

|- | |||

|Displacement/Cyl | |||

|3736 cm3 | |||

|- | |||

|Compression ratio | |||

|19.5:1 | |||

|- | |||

|Max speed | |||

|2200 RPM | |||

|} | |||

ENGINE SPECFICATIONS - For the main engine dimensions, | |||

we decided on the specifications indicated in | |||

Revisjonen fra 30. des. 2025 kl. 22:06

Tilbake til oversikt over Mercedesmotorer

Arrangements have been made for the MB 870 engine series to include the following types:

MB 870 Ka 6-cylinder V engine with exhaust gas turbocharging and- internal charge air cooling

MB 871 Ka 8-cylinder V engine with exhaust gas turbocharging and internal charge air cooling

MB 872 Ka 10-cylinder V engine with exhaust gas turbocharging and internal charge air cooling

MB 873 Ka 12-cylinder V engine with exhaust gas turbocharging and internal charge air cooling

From "Daimler-Benz High output engines - a study in compact design.

A paper published by SAE, written by O. Herschmann of Daimler-Benz A.G. 1967

ABSTRACT: To meet the increased power demands for special vehicles, Daimler-Benz started the development of a compact, liquid-cooled diesel engine family some 12 years ago. The objective of this development was to obtain a maximum output from a given bulk volume while maintaining well-known diesel engine characteristics. The basic layout of this family was such as to offer a high degree of versatility and to allow continued development. Based on this existing engine family, the development of a 1500 hp engine was started about three years ago. Reducing the bulk volume and, at the same time, increasing the specific output, resulted in a very compact engine, producing 28.4 hp per cu ft of bulk volume. This paper presents some of the considerations made in the design of these engines and some interesting technical data.

-

IN THE HISTORY of Daimler-Benz, as the oldest automomobile manufacturer in the world, the development of compact high-performance engines has a long-standing tradition.

It all started with the development of an engine for vehicle application some 80 years ago. This engine had to be more compact and lighter in weight than the internal combustion engines of that time. The development of this engine thus marked the beginning of what is called the "automotive age."

In the future course of time, there followed the development of various engines for which compact design and high output were of decisive significance; for example, engines for racing cars, airships, and airplanes. At the same time, diesel engines for trucks, passenger cars, and locomotive and marine applications were included in the development program.

Through the progress made with these engines, all types of vehicle development were stimulated. Within the framework of this development, it proved necessary to expand knowledge on the thermodynamic and combustion processes taking place within the engine, as well as to create the necessary equipment for basic research, computation techniques, and methods of measurement. At the same time, research was directed towards the mechanical and thermal loading of engine components, engine behavior, and adaptation for specific applications.

Based on this knowledge, the development of a new family of four-stroke cycle diesel engines began about 12 years ago. For these engines, high output at minimum bulk volume was of special importance in meeting the particular requirement for installation in special vehicles. Furthermore, the basic design of this engine family had to be such as to permit continued development.

For any such development, one must have a clear idea of the requirements and of the possibilities that exist to accomplish the goal set. Only after careful evaluation of all aspects can a decision be made on the direction that development should take. This paper reports the manner in which Daimler-Benz has dealt with these problems.

BASIC CONSIDERATIONS AS TO ENGINE CONFIGURATIONS

The first decision to be made is how to lay out the engine with respect to required output. This in turn raises a number of questions. For example, is the engine underrated or overrated for the vehicle in question? In other words, will the engine be operated more or less often at high loads? Is there a weight increase to be anticipated for the vehicle, or will the requirements rise in respect to mobility?

The answer to these questions and the existing development schedule determine the basic engine specifications (displacement, mean effective pressure, engine speed, and piston speed) in accordance with the state-of-the-art and the foreseeable progress in this field.

From an economical point of view, the basic design of an engine should remain unchanged for as long as possible.

Therefore, it seemed expedient to us to plan the layout in

such a manner that would lead to an engine family. With

such an engine family, changing demands from the vehicle

side as well as the requirements of a new project can best

be met, while also offering the logistic advantage of a great

many identical parts.

At this point, the next decision is to select the optimum

engine configuration. We believe the V-90 deg arrangement

to be an optimum solution for an engine family for

the following reasons:

1. It represents an ideal in that the first-order reciprocating

forces can be balanced by counterweights on the crankshaft.

2. It offers a good compromise with regard to the housing

of auxiliary units, and offers good accessibility of the

engine from the top.

3. It offers a favorable ratio of height to width.

Fig. 1 shows the results of a design study for various V-angles.

Going from 60 to 45 deg does not yield any further

decrease of width; the step from 120 to 180 deg does not further decrease the height. As can be seen further from

Fig. 1, the frontal area of the V-90 deg engine almost attains

a minimum.

COOLING SYSTEM - When faced with the question of

whether to choose liquid-cooling or aircooling, we decided

on liquid-cooling for the following reasons:

1. We are of the opinion that the liquid-cooled engine

allows a certain output within a given envelope to be obtained

by simpler means, and feel that it involves fewer

risks.

2. We have found the installation space required for liquid-cooled

engines, including radiator, to be less than that

of an aircooled engine of identical displacement. For the

latter, the cooling air ducts must also be taken into consideration.

3. When installed, the liquid-cooled engine offers the

advantage that the radiator may be located away from the

engine. The engine can thus be mounted in places where,

for various reasons, the installation of cooling air ducting

would be difficult.

4. The dated argument, that the liquid-cooled engine is

more susceptible to trouble, more vulnerable, and more

complex on account of its cooling system and the necessary

piping, has become invalid, since the modem aircooled high-

performance engine also needs efficient oil coolers at exposed

locations and similarly requires piping.

The installation of the transmission oil cooler, which is

indispensable for all modern transmissions, can be accomplished

more easily with liquid-cooling than with aircooling.

5. Engine warmup under arctic conditions appears to be

simpler with liquid-cooling.

The fact that the liquid-cooled engine requires a liquid

coolant is more than balanced by the above-mentioned advantages,

particularly since this coolant is not required for

consumption but need only be replenished.

FOUR-STROKE CYCLE - In making the choice between

the two or four-stroke cycle, we decided to employ the latter,

not only because we have a great deal of experience

with it but also because investigations conducted on two -

stroke cycle engines did not encourage us to proceed with

this development.

| Cylinder arrangements | V-90 |

| Type | Four stroke cycle |

| Combustion system | Prechamber |

| Stroke | 175 mm |

| Bpre | 165 mm |

| Displacement/Cyl | 3736 cm3 |

| Compression ratio | 19.5:1 |

| Max speed | 2200 RPM |

ENGINE SPECFICATIONS - For the main engine dimensions,

we decided on the specifications indicated in