MB 873: Forskjell mellom revisjoner

mIngen redigeringsforklaring |

mIngen redigeringsforklaring |

||

| Linje 115: | Linje 115: | ||

engines. | engines. | ||

Fig. 8 shows the prechamber temperature characteristics | Fig. 8 shows the prechamber temperature characteristics of our engine plotted against load and speed. The small | ||

of our engine plotted against load and speed. The small | influence of load on the prechamber wall temperature is to be particularly noted. Whereas the exhaust temperature varies | ||

influence of load on the prechamber wall temperature is to | by about 800 F over the full range of engine performance, the prechamber temperature varies only by about 204 degrees. The hot walls of the prechamber thus help to burn even | ||

be particularly noted. Whereas the exhaust temperature varies | |||

by about 800 F over the full range of engine performance, | |||

the prechamber temperature varies only by about | |||

fuels of poor self-ignition quality. Of course, extensive development | fuels of poor self-ignition quality. Of course, extensive development | ||

work is needed to obtain these favorable characteristics | work is needed to obtain these favorable characteristics in conjunction with the required durability. Optimum prechamber size and most favorable combustion- | ||

in conjunction with the required durability. | chamber design are the result of many tests and endurance runs. At a compression ratio of 19.5:1, we selected a prechamber | ||

Optimum prechamber size and most favorable combustion- | |||

chamber design are the result of many tests and endurance | |||

runs. At a compression ratio of 19.5:1, we selected a prechamber | |||

with a volume equal to 25% of the compression volume. | with a volume equal to 25% of the compression volume. | ||

Fig. 9 shows characteristic main chamber pressure diagrams | Fig. 9 shows characteristic main chamber pressure diagrams | ||

obtained with varying injection timing. The optimum | obtained with varying injection timing. The optimum with respect to thermal efficiency and mechanical | ||

with respect to thermal efficiency and mechanical | |||

loading lies between diagrams 2 and 3. It also shows that | loading lies between diagrams 2 and 3. It also shows that | ||

the difference in injection timing between combat fuel and | the difference in injection timing between combat fuel and | ||

diesel fuel is only 2 deg; that is, both fuels can be used with | diesel fuel is only 2 deg; that is, both fuels can be used with | ||

practically the same injection timing setting. In contrast | practically the same injection timing setting. In contrast to this we have found that, for direct injection, the difference | ||

to this we have found that, for direct injection, the difference | in injection timing between combat fuel and diesel fuel amounts to 8-10 deg. | ||

in injection timing between combat fuel and diesel | |||

fuel amounts to 8-10 deg. | |||

VALVE TRAIN - When selecting the valve train, we | VALVE TRAIN - When selecting the valve train, we | ||

strove for a simple design which would insure positively controlled | strove for a simple design which would insure positively controlled | ||

| Linje 151: | Linje 142: | ||

blower, if used. The automatic variable timing device is | blower, if used. The automatic variable timing device is | ||

incorporated into this gear as shown in Fig. 11. | incorporated into this gear as shown in Fig. 11. | ||

The most favorable compromise between masses and rigidity | The most favorable compromise between masses and rigidity | ||

of the valve train was found by analog computer studies | of the valve train was found by analog computer studies | ||

| Linje 169: | Linje 161: | ||

volumetric efficiency obtained with it over the whole | volumetric efficiency obtained with it over the whole | ||

speed range. | speed range. | ||

CYLINDER BLOCK - The cylinder block is a one-piece | CYLINDER BLOCK - The cylinder block is a one-piece | ||

light alloy casting. With the firmly bolted sump housing, | light alloy casting. With the firmly bolted sump housing, | ||

| Linje 198: | Linje 191: | ||

section of the wall under compressive stress, thus offsetting | section of the wall under compressive stress, thus offsetting | ||

the tension stresses resulting from the combustion force P. | the tension stresses resulting from the combustion force P. | ||

RECIPROCATING PARTS - In the original layout, the | RECIPROCATING PARTS - In the original layout, the | ||

crankshaft was dimensioned to give high rigidity and thus | crankshaft was dimensioned to give high rigidity and thus | ||

| Linje 227: | Linje 221: | ||

programmed by tape and can be varied over the entire range | programmed by tape and can be varied over the entire range | ||

of engine operation. | of engine operation. | ||

OIL PAN AND LUBRICATING OIL SYSTEM - The minimum | OIL PAN AND LUBRICATING OIL SYSTEM - The minimum | ||

height of the dry sump oil pan is determined by the | height of the dry sump oil pan is determined by the | ||

| Linje 251: | Linje 246: | ||

NEW 1500 HP ENGINE | NEW 1500 HP ENGINE | ||

About three years ago, we were requested to develop a | |||

1500 hp engine. This engine had to be smaller in height and more compact than any predecessor and still maintain the | About three years ago, we were requested to develop a 1500 hp engine. This engine had to be smaller in height and more compact than any predecessor and still maintain the well-known diesel engine characteristics such as good fuel economy, standard lube oil requirements, reliability, and low maintenance requirements. Based on the aforementioned d e c 3 l o p m e n t stage of our engine family, we found that a modified configuration of our 12-cylinder engine MB 840 would satisfy the requirements with respect to output as well as available space. To obtain 1500 hp or 125 hp per cylinder, a bmep of 13.44 bar at a speed of 2200 rpm is required. In this range, we have wide experience. | ||

well-known diesel engine characteristics such as good fuel | |||

economy, standard lube oil requirements, reliability, and | The transmission for the project in | ||

low maintenance requirements. | |||

Based on the aforementioned d e c 3 l o p m e n t stage of our | |||

engine family, we found that a modified configuration of | |||

our 12-cylinder engine MB 840 would satisfy the requirements | |||

with respect to output as well as available space. | |||

To obtain 1500 hp or 125 hp per cylinder, a bmep of | |||

have wide experience. The transmission for the project in | |||

question required a maximum engine speed of 2600 rpm. | question required a maximum engine speed of 2600 rpm. | ||

Preliminary tests on a single-cylinder engine showed that | Preliminary tests on a single-cylinder engine showed that | ||

Revisjonen fra 31. des. 2025 kl. 15:08

Tilbake til oversikt over Mercedesmotorer

Arrangements have been made for the MB 870 engine series to include the following types:

MB 870 Ka 6-cylinder V engine with exhaust gas turbocharging and- internal charge air cooling

MB 871 Ka 8-cylinder V engine with exhaust gas turbocharging and internal charge air cooling

MB 872 Ka 10-cylinder V engine with exhaust gas turbocharging and internal charge air cooling

MB 873 Ka 12-cylinder V engine with exhaust gas turbocharging and internal charge air cooling

From "Daimler-Benz High output engines - a study in compact design.

A paper published by SAE, written by O. Herschmann of Daimler-Benz A.G. 1967

ABSTRACT: To meet the increased power demands for special vehicles, Daimler-Benz started the development of a compact, liquid-cooled diesel engine family some 12 years ago. The objective of this development was to obtain a maximum output from a given bulk volume while maintaining well-known diesel engine characteristics. The basic layout of this family was such as to offer a high degree of versatility and to allow continued development. Based on this existing engine family, the development of a 1500 hp engine was started about three years ago. Reducing the bulk volume and, at the same time, increasing the specific output, resulted in a very compact engine, producing 28.4 hp per cu ft of bulk volume. This paper presents some of the considerations made in the design of these engines and some interesting technical data.

-

IN THE HISTORY of Daimler-Benz, as the oldest automomobile manufacturer in the world, the development of compact high-performance engines has a long-standing tradition.

It all started with the development of an engine for vehicle application some 80 years ago. This engine had to be more compact and lighter in weight than the internal combustion engines of that time. The development of this engine thus marked the beginning of what is called the "automotive age."

In the future course of time, there followed the development of various engines for which compact design and high output were of decisive significance; for example, engines for racing cars, airships, and airplanes. At the same time, diesel engines for trucks, passenger cars, and locomotive and marine applications were included in the development program.

Through the progress made with these engines, all types of vehicle development were stimulated. Within the framework of this development, it proved necessary to expand knowledge on the thermodynamic and combustion processes taking place within the engine, as well as to create the necessary equipment for basic research, computation techniques, and methods of measurement. At the same time, research was directed towards the mechanical and thermal loading of engine components, engine behavior, and adaptation for specific applications.

Based on this knowledge, the development of a new family of four-stroke cycle diesel engines began about 12 years ago. For these engines, high output at minimum bulk volume was of special importance in meeting the particular requirement for installation in special vehicles. Furthermore, the basic design of this engine family had to be such as to permit continued development.

For any such development, one must have a clear idea of the requirements and of the possibilities that exist to accomplish the goal set. Only after careful evaluation of all aspects can a decision be made on the direction that development should take. This paper reports the manner in which Daimler-Benz has dealt with these problems.

BASIC CONSIDERATIONS AS TO ENGINE CONFIGURATIONS

The first decision to be made is how to lay out the engine with respect to required output. This in turn raises a number of questions. For example, is the engine underrated or overrated for the vehicle in question? In other words, will the engine be operated more or less often at high loads? Is there a weight increase to be anticipated for the vehicle, or will the requirements rise in respect to mobility?

The answer to these questions and the existing development schedule determine the basic engine specifications (displacement, mean effective pressure, engine speed, and piston speed) in accordance with the state-of-the-art and the foreseeable progress in this field.

From an economical point of view, the basic design of an engine should remain unchanged for as long as possible.

Therefore, it seemed expedient to us to plan the layout in such a manner that would lead to an engine family. With such an engine family, changing demands from the vehicle side as well as the requirements of a new project can best be met, while also offering the logistic advantage of a great many identical parts.

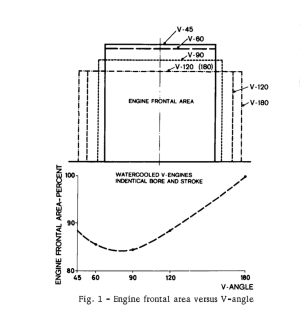

At this point, the next decision is to select the optimum engine configuration. We believe the V-90 degree arrangement to be an optimum solution for an engine family for the following reasons:

1. It represents an ideal in that the first-order reciprocating forces can be balanced by counterweights on the crankshaft.

2. It offers a good compromise with regard to the housing of auxiliary units, and offers good accessibility of the engine from the top.

3. It offers a favorable ratio of height to width.

Fig. 1 shows the results of a design study for various V-angles. Going from 60 to 45 deg does not yield any further decrease of width; the step from 120 to 180 deg does not further decrease the height. As can be seen further from Fig. 1, the frontal area of the V-90 deg engine almost attains a minimum.

COOLING SYSTEM - When faced with the question of whether to choose liquid-cooling or aircooling, we decided on liquid-cooling for the following reasons:

1. We are of the opinion that the liquid-cooled engine allows a certain output within a given envelope to be obtained by simpler means, and feel that it involves fewer risks.

2. We have found the installation space required for liquid-cooled engines, including radiator, to be less than that of an aircooled engine of identical displacement. For the latter, the cooling air ducts must also be taken into consideration.

3. When installed, the liquid-cooled engine offers the advantage that the radiator may be located away from the engine. The engine can thus be mounted in places where, for various reasons, the installation of cooling air ducting would be difficult.

4. The dated argument, that the liquid-cooled engine is more susceptible to trouble, more vulnerable, and more complex on account of its cooling system and the necessary piping, has become invalid, since the modem aircooled high-performance engine also needs efficient oil coolers at exposed locations and similarly requires piping.

The installation of the transmission oil cooler, which is indispensable for all modern transmissions, can be accomplished more easily with liquid-cooling than with aircooling.

5. Engine warmup under arctic conditions appears to be simpler with liquid-cooling. The fact that the liquid-cooled engine requires a liquid coolant is more than balanced by the above-mentioned advantages, particularly since this coolant is not required for consumption but need only be replenished.

FOUR-STROKE CYCLE - In making the choice between the two or four-stroke cycle, we decided to employ the latter, not only because we have a great deal of experience with it but also because investigations conducted on two-stroke cycle engines did not encourage us to proceed with this development.

| Tabell 1 - Engine Specifications | |

|---|---|

| Cylinder arrangements | V-90 |

| Type | Four stroke cycle |

| Combustion system | Prechamber |

| Stroke | 175 mm |

| Bpre | 165 mm |

| Displacement/Cyl | 3736 cm3 |

| Compression ratio | 19.5:1 |

| Max speed | 2200 RPM |

ENGINE SPECFICATIONS - For the main engine dimensions, we decided on the specifications indicated in Table 1. The layout of the engines is such as to allow maximum versatility; for example, naturally aspirated, mechanically supercharged, or turbocharged. At the basic layout stage, the mechanically driven supercharger was still considered because its space and weight requirements are very low with respect to the output gain obtained. Furthermore, at that time the exhaust gas driven compact supercharger was still in the development stage.

Depending on the mode of charging, the outputs listed in Table 2, per cylinder, can be obtained. We planned a family of 6, 8, 10 and 12-cylinder engines. The output range covered and the horsepower-to-bulk volume ratio obtained is shown in Fig. 2

Figs. 3 and 4 show some examples of our engines as installed in large numbers in special vehicles.

DESIGN FEATURES - Fig. 5 clearly shows our design philosophy: compact design and simple basic engine structure. In a given envelope, a maximum displacement volume is accommodated. Here, all auxiliary units such as generator, starter, oil reserve compartment, oil cooler, and intake and exhaust manifolds are housed within the rectangle determinedby the main dimensions of the engine. In order to save weight, all cast components are made of light alloys, wherever possible. As previously stated, the engines should have a high degree of versatility. Therefore, several power takeoffs were provided. Up to 500 hp is available at the front end of the crankshaft; 50 hp each can be taken off at two other locations.

CYLINDER HEAD - The individual cylinder heads were designed to provide a low but rigid structure. The dry type prechamber is centrally located. This insures good support of the bottom and allows easy removal and installation of the glow plug. Four parallel valves (two intake and two exhaust) are arranged around the prechamber. Chrome-molybdenum valve seat inserts are standard; valve rotators are provided for the intake valves.

Eight equally spaced cylinder head stud bolts around the cylinder circumference - - two each being common with the adjacent cylinder head - - insure uniform load distribution of the gas forces. Eight cooling water passages from the crankcase guarantee uniform cooling, even of critical spots in the cylinder head. Lube oil and diesel fuel are positively separated, due to the special design feature as shown in Fig. 7. The clearance of all four valves can be adjusted from above. Similarly, the injection system is accessible from the top, the timing gear being no obstacle.

COMBUSTION SYSTEM - Within our company's engine program, we employ the direct injection system as well as the prechamber system. Therefore, we are able to compare the characteristics of both systems fairly well. With this engine family, the main objective was to obtain high outputs at high volumetric efficiency to provide good fuel economy and to keep the mechanical loading as low as possible. Good cold startability and the ability to burn a wide range of fuels were additional and important aspects. Thus, we decided to adopt the prechamber system. The good cold start performance obtained with our combustion system can be seen from Table 3. Tests were carried out with two different grades of lube oils (SAE 10 and SAE 5) and a 24 hr cold soaked engine in a cold room. Cold start tests under arctic conditions in Canada have also given proof of the excellent cold starting characteristics of our engines.

Fig. 8 shows the prechamber temperature characteristics of our engine plotted against load and speed. The small influence of load on the prechamber wall temperature is to be particularly noted. Whereas the exhaust temperature varies by about 800 F over the full range of engine performance, the prechamber temperature varies only by about 204 degrees. The hot walls of the prechamber thus help to burn even fuels of poor self-ignition quality. Of course, extensive development work is needed to obtain these favorable characteristics in conjunction with the required durability. Optimum prechamber size and most favorable combustion- chamber design are the result of many tests and endurance runs. At a compression ratio of 19.5:1, we selected a prechamber with a volume equal to 25% of the compression volume. Fig. 9 shows characteristic main chamber pressure diagrams obtained with varying injection timing. The optimum with respect to thermal efficiency and mechanical loading lies between diagrams 2 and 3. It also shows that the difference in injection timing between combat fuel and diesel fuel is only 2 deg; that is, both fuels can be used with practically the same injection timing setting. In contrast to this we have found that, for direct injection, the difference in injection timing between combat fuel and diesel fuel amounts to 8-10 deg.

VALVE TRAIN - When selecting the valve train, we strove for a simple design which would insure positively controlled valve motion over the whole operating speed range. Detailed studies resulted in the adoption of the valve train shown in Fig. 10. This design features a camshaft located high up in the crankcase, short push rods, and rigid rocker arms. To reduce the structural height, the rocker arm bedding was kept as low as possible. The camshafts are driven from the front crankshaft end via idler gears. This allows good access to the whole gear train which requires only six gears. The central upper gear also drives the in-line fuel injection pump and mechanical blower, if used. The automatic variable timing device is incorporated into this gear as shown in Fig. 11.

The most favorable compromise between masses and rigidity of the valve train was found by analog computer studies on various valve train versions. The valve train found to be best was then built and compared by test with the computer results. Fig. 12 presents the result of such a study. It shows a comparison of the measured and calculated dynamic behavior of the intake valve train at two different speeds. As indicated, the difference between the measured and calculated valve lift curves is hardly detectable. Similarly, the calculated push rod forces compare favorably with those measured. Cam and valve are always positively connected during the whole valve opening period even at 30% over- speed. Our experience has shown that a short force separation in the valve train which might occur at overspeeds greater than 30% does not affect the durability of the moving parts of the valve mechanism. The advantage of this valve train design lies in its simplicity and in the good overall volumetric efficiency obtained with it over the whole speed range.

CYLINDER BLOCK - The cylinder block is a one-piece light alloy casting. With the firmly bolted sump housing, it forms a rigid beam. Great care was applied in the design to insure uniform distribution of stresses. The gas forces are introduced into the housing by a large number of stretch studs. Uniform loading of the bearing structure is achieved by using forged bearing caps connected to the housing by four stud bolts. The oil cooler housing is cast onto the side and forms an integral part of the cylinder block (Fig. 13). In order to save weight, the aim in any design, particularly in that of the crankcase, is to avoid overdimension- ing; on the other hand, the structure must take the occurring stresses for the anticipated life of the unit. In pursuing this objective, the designer has a number of design aids at hand. One of these is the visualization of stresses by photoelas- ticity. How this was applied in the design of the main bearing section is shown in the following example. Figs. 14a and 14b represent the cross section of the crank- case with both long and short inner studs. The stress patterns shown in the picture result from the bolt forces and and the combustion force P. Applying two short inner studs results in a high concentration of force lines around the main bearing bore, causing unwanted distortions. Furthermore, the flux of the force and interferes and, at the end of the blind holes, unfavorable tension stresses caused by the combustion force P occur. All these disadvantages are avoided with the two long inner studs. They put a large section of the wall under compressive stress, thus offsetting the tension stresses resulting from the combustion force P.

RECIPROCATING PARTS - In the original layout, the crankshaft was dimensioned to give high rigidity and thus provide ample reserve with respect to power increase. This foresight has proved its value because no changes have had to be made on the basic design to date. As is usual with engines of this type, two connecting rods are placed side-by- side on each crank throw. In order to allow connecting rod removal through the cylinder bore, its big end is split at an angle and the mating surfaces are serrated to insure alignment and to eliminate shear stresses on the rod bolts. An enlarged view of the reciprocating parts is shown in Fig. 15. The pistons are aluminum forgings and feature three compression rings and two oil control rings. Valve clearance pockets are machined in the top of the piston. For outputs greater than 90 hp/cylinder, the piston is oil cooled by an oil jet, mounted in the crankcase. The photoelastic method can also be successfully used in designing the connecting rod. Fig. 16 (left) shows the big end of a connecting rod model under inertial force loading. The resulting stress pattern around the bore is shown graphically on the right of the figure. As can be seen, the stresses, particularly those in the cap, are rather uniform. The highest stresses occur near the bolt head supporting surface and on the short arm of the rod. The final shape of such a connecting rod is not released for production unless it successfully passes various dynamic loading tests. For this purpose, we have built a special machine for simulating dynamic loading. The load cycles are programmed by tape and can be varied over the entire range of engine operation.

OIL PAN AND LUBRICATING OIL SYSTEM - The minimum height of the dry sump oil pan is determined by the dimensions of the crank assembly and the inclined position operating requirements. Oil splashing must be avoided even under extreme inclinations. That is, the oil feed ducts to the scavenge pumps placed in the front and in the rear of the pan must be so designed as to guarantee complete scavenging. This also requires careful matching of the entire lube oil circuit to the engine. The oil pumps are lined up in the pan bottom and are driven from the crankshaft front end. In the lube oil system shown in Fig. 17, all lines are internal, and the oil is directed from the pressure pump to the oil cooler. From there, it flows through a bank of oil filters to the lube oil galleries in the block and then to the bearings. Oil flowing back from the engine is picked up by the scavenge pumps and fed to the reserve compartment. In order to test the lube oil system and the inclined position operation, a test bed was developed which allows simulation of all inclinations possible in field service at full load. The test bed (Fig. 18) is hydraulically operated with infinitely variable adjustment, maximum inclination being ±40 deg in all directions.

NEW 1500 HP ENGINE

About three years ago, we were requested to develop a 1500 hp engine. This engine had to be smaller in height and more compact than any predecessor and still maintain the well-known diesel engine characteristics such as good fuel economy, standard lube oil requirements, reliability, and low maintenance requirements. Based on the aforementioned d e c 3 l o p m e n t stage of our engine family, we found that a modified configuration of our 12-cylinder engine MB 840 would satisfy the requirements with respect to output as well as available space. To obtain 1500 hp or 125 hp per cylinder, a bmep of 13.44 bar at a speed of 2200 rpm is required. In this range, we have wide experience.

The transmission for the project in question required a maximum engine speed of 2600 rpm. Preliminary tests on a single-cylinder engine showed that the speed increase from 2200 to 2600 rpm was possible by reducing the stroke. In doing so, no new problems regarding the combustion system or the valve train arose. The requirement for a low installation height was met by introducing new ideas in the design of the cylinder head, intake manifold, injection pump, and oil pan (Fig. 19). This modified 12-cylinder engine is called MB 873. It features two turbochargers and two intercoolers connected to the engine cooling system. Table 4 and Fig. 20 represent a comparison of the two 12-cylinder 1500 hp engines with respect to engine specifications and general dimensions. The progress in the development of the MB 873 becomes apparent when comparing the hp to bulk volume figures. Dictated by the specific installation requirements, the two turbochargers and the intercoolers are side-mounted (Fig. 21). This leads to a very favorable space saving arrangement of the air cleaners which are rigidly connected to the engine; consequently, the usual flexible joints are superfluous. Installation and removal of the entire power package is thus greatly simplified. The full-load characteristics of the engine are shown in Fig. 22. The torque curve obtained is favorable for vehicle propulsion requirements. The graph also includes the m a x imum combustion pressures. Because of the smooth combustion obtainable with our prechamber, the maximum pressure at the rating point is relatively low. The fuel map obtained with the pre-prototype engine operated on diesel fuel is shown in Fig. 23. The overall good fuel consumption in the range of anticipated vehicle opera-tion is to be noted, as well as the interrelation between fuel consumption, required range of action, and fuel tank volume. During the extensive testing program with this engine, no serious troubles were encountered. The appearance of the disassembled engine parts was always good; this is noteworthy in view of the fact that S-l oils were used throughout the tests. CONSIDERATIONS REGARDING BULK VOLUME OF TOTAL POWER PACKAGE Experience over the past years has shown that, with the trend toward more and more compact engines, the auxiliary units necessary for engine operation must be included in the development program. Otherwise, the progress made in reducing the bulk volume of the engine may become insignificant with respect to the complete power package. This fact induced us and our suppliers to keep a critical eye on the functional design and space saving arrangement of all auxiliary units (oil filter, air cleaner, cooling system, oil cooler, and so on). At the same time, we also included main units such as the transmission assembly in our design concept.

It would be beyond the scope of this paper to give a detailed report on all these areas. For the time being, we wish to point out that an effort is being made to regard the engine not as an isolated unit but as an organic and functional part of the whole power package. Fig. 24 proves the success of our efforts. It demonstrates the reduction in volume of the power package as well as of the engine which has been achieved. It also serves to show the relatively low bulk volume of the engine compared to that of the entire power package. SUMMARY The principal considerations applying during development of an engine family intended for special purposes have been reported. Also presented were characteristic values of this engine family and those of a newly developed, especially compact 1500hp engine. By the adoption of carefully evaluated compact design concepts and the application of proven combustion and supercharging methods, we have succeeded in halving the engine bulk volume as well as that of the whole power package during the past 10 years. We will continue our efforts to make the diesel engine and entire power package even more attractive, and we hope that the new engine will be the basis for a new engine family which will make further power increases possible. The feasibility of this has been proven by single-cylinder engine tests where 175hp per cylinder has already been reached. Wherever installation space, operating ability, reliability, maintenance, and fuel consumption are prime considerations, this new compact engine constitutes a rival which cannot be ignored for any other powerplant available today.